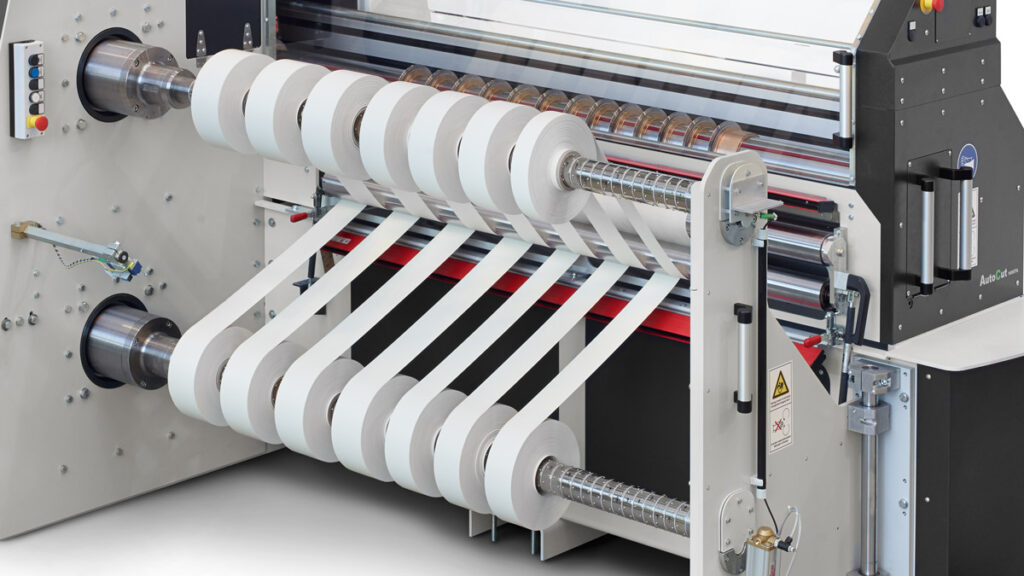

Durable slitting equipment is essential for industries that demand precision, speed, and reliability in material processing. Designed to deliver consistent, clean cuts, this advanced machinery plays a critical role in sectors such as packaging, textiles, paper, plastics, and metalworking. Built with high-quality components and engineered for long-term performance, durable slitting machines stand out for their ability to maintain exceptional cutting accuracy over extended periods of use, even under high production volumes. These machines are crafted using robust materials that resist wear and tear, ensuring stability and reducing the frequency of maintenance or part replacements. This not only increases uptime but also significantly lowers operational costs, making them a smart investment for businesses focused on quality and efficiency. One of the key advantages of modern slitting equipment is its precision control. Featuring advanced automation and control systems, these machines allow for easy adjustments in speed, pressure, and blade alignment to match the specific requirements of different materials. This flexibility ensures clean, burr-free cuts with minimal edge fraying or distortion, which is particularly important when working with delicate or high-value substrates.

Whether processing thin films or heavy-duty metal coils, durable slitting machine maintains consistent results, leading to better product quality and enhanced customer satisfaction. In addition to precision, user-friendly operation is another hallmark of durable slitting systems. Many models come equipped with intuitive touch-screen interfaces and automated settings, allowing operators to manage production runs efficiently and with minimal training. Safety features are also integrated into the design, including emergency stop functions, protective covers, and automatic blade positioning, ensuring a secure working environment. These thoughtful additions help streamline workflow and reduce downtime due to errors or accidents. Moreover, the energy-efficient nature of many slitting machines contributes to sustainable production practices. By optimizing motor functions and reducing waste through accurate cutting, they help companies lower their environmental impact while maintaining high throughput.

Many durable slitting units also support quick changeovers between different materials or job specifications, adding to their versatility and helping manufacturers meet tight deadlines without compromising on quality. Overall, durable slitting equipment is an indispensable asset for modern manufacturing operations. It combines rugged construction with precision technology to deliver unmatched performance in cutting operations. Businesses that invest in these machines benefit from improved product consistency, reduced material waste, increased production speeds, and lower long-term costs. With a focus on reliability, ease of use, and adaptability, these machines not only meet current industrial demands but also position companies to scale up effectively and stay competitive in evolving markets. For KETE manufacturers seeking efficiency, accuracy, and longevity in their operations, durable slitting equipment offers a compelling solution that consistently delivers clean, professional results.